- Introduction

- Maintenance

- Preparation

- Service specifications

- Diagnostics

- 2JZ-GE Engine

- 2JZ-GTE Engine

- 2JZ-GTE Turbocharging

- 2JZ-GE Emission control

- 2JZ-GTE Emission control

- 2JZ-GE SFI

- 2JZ-GTE SFI

- Cooling

- Lubrication

- Ignition system 2JZ-GE

- Ignition system 2JZ-GTE

- Starting system

- Charging system

- Clutch

- W58 manual transmission

- V160 manual transmission

- A340E 2JZ-GE automatic transmission

- A340E 2JZ-GTE automatic transmission

- Propeller shaft

- Suspension and axle

- Brake system

- Steering

- Supplemental restraint system

- Body electrical system

- Body

- Air conditioning system

- Use fender, seat and floor covers to keep the vehicle clean and prevent damage.

- During disassembly, keep parts in the appropriate order to facilitate reassembly.

- Observe the following:

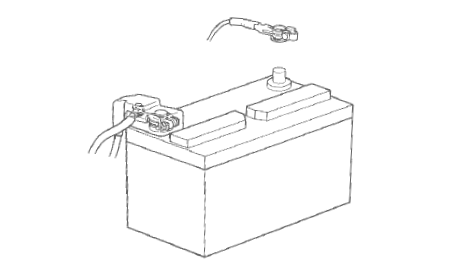

- Before performing electrical work, disconnect the negative (–) terminal cable from the battery.

- If it is necessary to disconnect the battery for inspection or repair, always disconnect the negative (–) terminal cable which is grounded to the vehicle body.

- To prevent damage to the battery terminal, loosen the cable nut and raise the cable straight up without twisting or prying it.

- Clean the battery terminals and cable ends with a clean shop rag. Do not scrape them with a file or other abrasive objects.

- Install the cable ends to the battery terminals with the nut loose, and tighten the nut after installation. Do not use a hammer to tap the cable ends onto the terminals.

- Be sure the cover for the positive (+) terminal is properly in place.

- Check hose and wiring connectors to make sure that they are secure and correct.

- Non–reusable parts

- Always replace cotter pins, gaskets, O–rings and oil seals etc. with new ones.

- Non–reusable parts are indicated in the component illustrations by the ” ○ ” symbol.

- Precoated parts

Precoated parts are bolts and nuts, etc. that are coated with a seal lock adhesive at the factory.- If a precoated part is retightened, loosened or caused to move in any way, it must be recoated with the specified adhesive.

- When reusing precoated parts, clean off the old adhesive and dry with compressed air. Then apply the specified seal lock adhesive to the bolt, nut or threads.

- Precoated parts are indicated in the component illustrations by the ” ⚫ ” symbol.

- When necessary, use a sealer on gaskets to prevent leaks.

- Carefully observe all specifications for bolt tightening torques. Always use a torque wrench.

- Use of special service tools (SST) and special service materials (SSM) may be required, depending on the nature of the repair. Be sure to use SST and SSM where specified and follow the proper work procedure. A list of SST and SSM can be found in the preparation part at the front of each section in this manual.

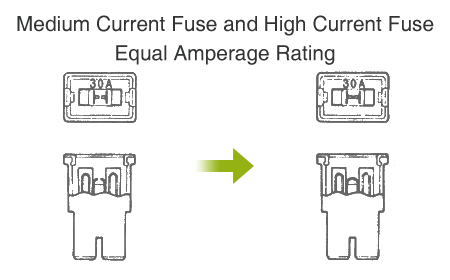

- When replacing fuses, be sure the new fuse has the correct amperage rating. DO NOT exceed the rating or use one with a lower rating.

| Illustration | Symbol | Part Name | Abbreviation |

|---|---|---|---|

|  | FUSE | FUSE |

|  | MEDIUM CURRENT FUSE | M-FUSE |

|  | HIGH CURRENT FUSE | H-FUSE |

|  | FUSIBLE LINK | FL |

|  | CIRCUIT BREAKER | CB |

- Care must be taken when jacking up and supporting the vehicle. Be sure to lift and support the vehicle at the proper locations.

- If the vehicle is to be jacked up only at the front or rear end, be sure to block the wheels at the opposite end in order to ensure safety.

- After the vehicle is jacked up, be sure to support it on stands. It is extremely dangerous to do any work on a vehicle raised on a jack alone, even for a small job that can be finished quickly.

- Observe the following precautions to avoid damage to the following parts:

- Do not open the cover or case of the ECU, ECM, PCM or TCM unless absolutely necessary. (If the IC terminals are touched, the IC may be destroyed by static electricity.)

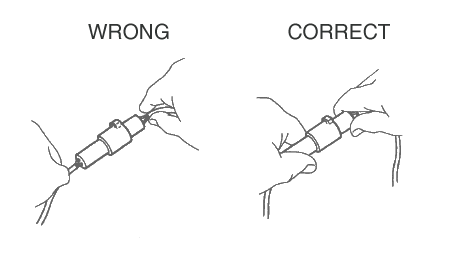

- To disconnect vacuum hoses, pull on the end, not the middle of the hose.

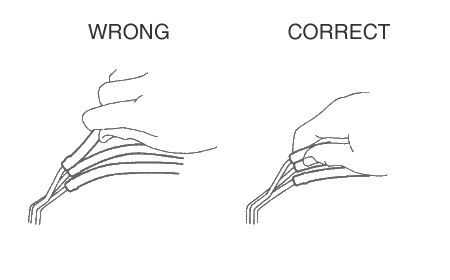

- To pull apart electrical connectors, pull on the connector itself, not the wires.

- Be careful not to drop electrical components, such as sensors or relays. If they are dropped on a hard floor, they should be replaced and not reused.

- When steam cleaning an engine, protect the distributor, air filter, and VCV from water.

- Never use an impact wrench to remove or install temperature switches or temperature sensors.

- When checking continuity at the wire connector, insert the tester probe carefully to prevent terminals from bending.

- When using a vacuum gauge, never force the hose onto a connector that is too large. Use a step–down adapter instead. Once the hose has been stretched, it may leak.

- Do not open the cover or case of the ECU, ECM, PCM or TCM unless absolutely necessary. (If the IC terminals are touched, the IC may be destroyed by static electricity.)

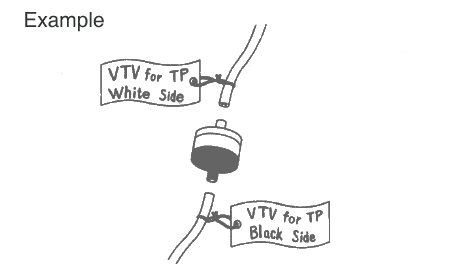

- Tag hoses before disconnecting them:

- When disconnecting vacuum hoses, use tags to identify how they should be reconnected.

- After completing a job, double check that the vacuum hoses are properly connected. A label under the hood shows the proper layout.

- Unless otherwise stated, all resistance is measured at an ambient temperature of 20°C (68°F). Because the resistance may be outside specifications if measured at high temperatures immediately after the vehicle has been running, measurements should be made when the engine has cooled down.