- Introduction

- Maintenance

- Preparation

- Service specifications

- Diagnostics

- 2JZ-GE Engine

- 2JZ-GTE Engine

- 2JZ-GTE Turbocharging

- 2JZ-GE Emission control

- 2JZ-GTE Emission control

- 2JZ-GE SFI

- 2JZ-GTE SFI

- Cooling

- Lubrication

- Ignition system 2JZ-GE

- Ignition system 2JZ-GTE

- Starting system

- Charging system

- Clutch

- W58 manual transmission

- V160 manual transmission

- A340E 2JZ-GE automatic transmission

- A340E 2JZ-GTE automatic transmission

- Propeller shaft

- Suspension and axle

- Brake system

- Steering

- Supplemental restraint system

- Body electrical system

- Body

- Air conditioning system

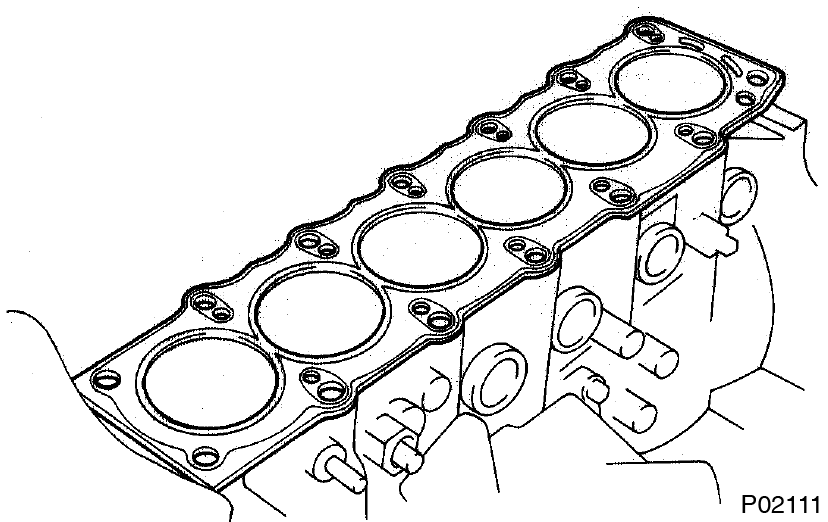

- Place cylinder head on cylinder block

- Place a new cylinder head gasket in position on the cylinder block. Be sure to install it correctly.

- Connect the heater hose to the heater union.

- Place the cylinder head in position on the cylinder head gasket.

- Place a new cylinder head gasket in position on the cylinder block.

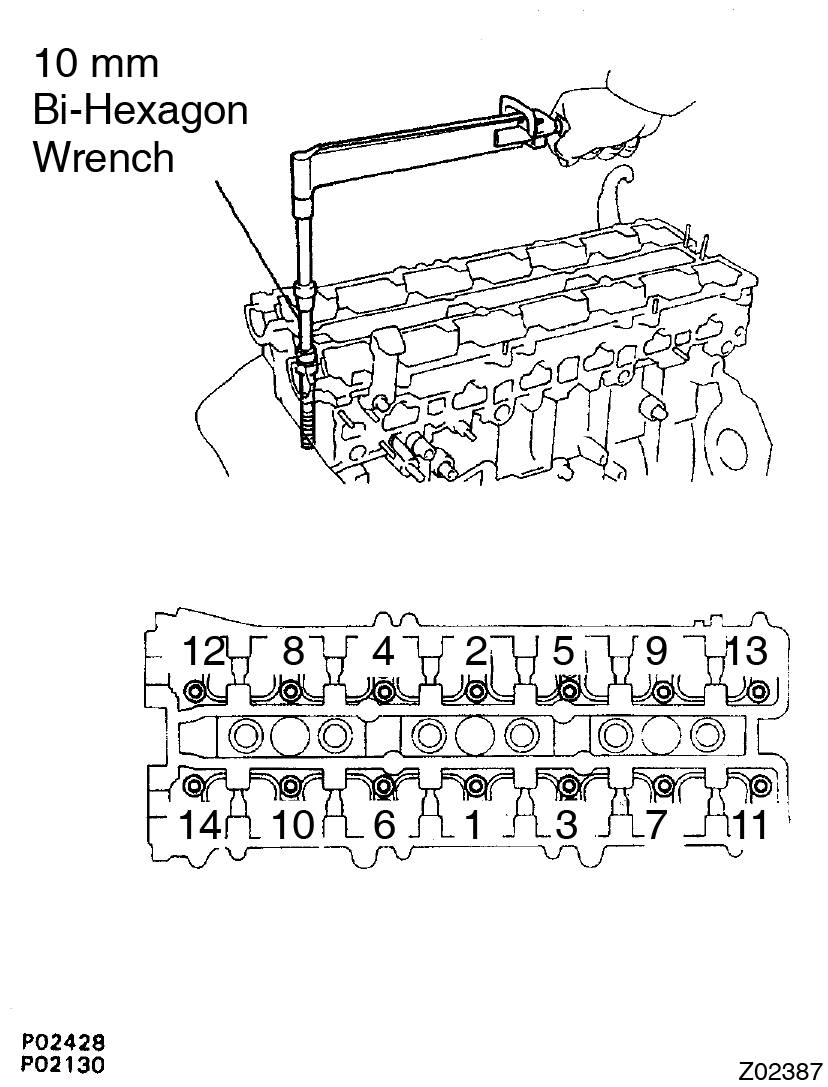

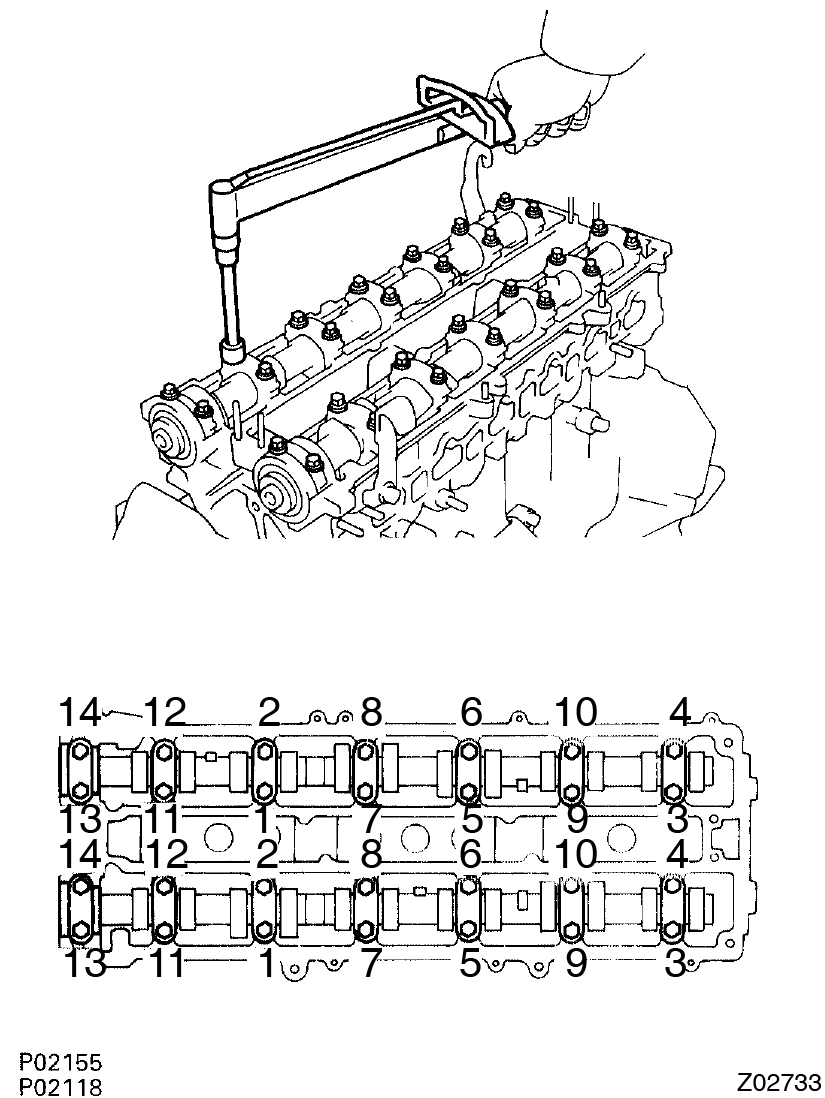

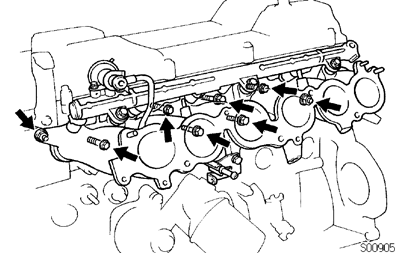

- Install cylinder head bolts

- The cylinder head bolts are tightened in 2 progressive steps (steps (c) and (f)).

- If any of bolts break or deform, replace them.

- Apply a light coat of engine oil on the threads and under the heads of the cylinder head bolts.

- Install the 14 plate washers to each cylinder head bolt.

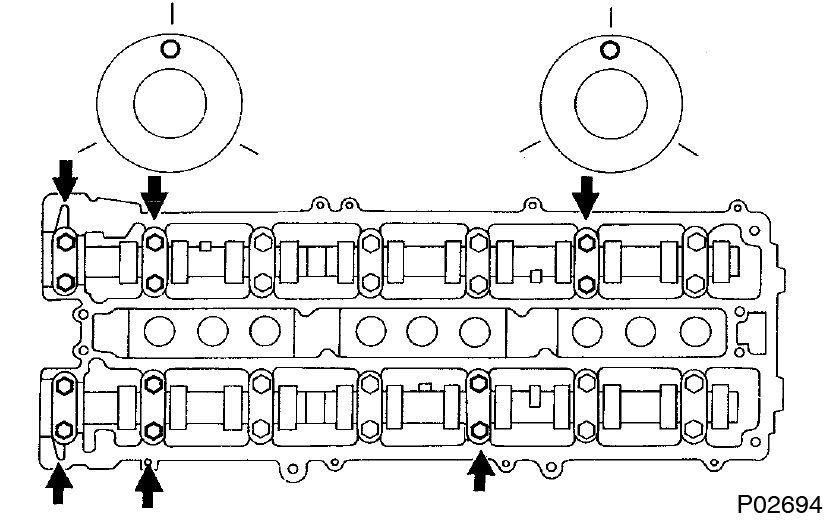

- Using a 10 mm bi-hexagon wrench, uniformly tighten the cylinder head bolts, in several passes, in the sequence shown.

Torque: 34 N·m (350 kgf·cm, 25 ft·lbf)

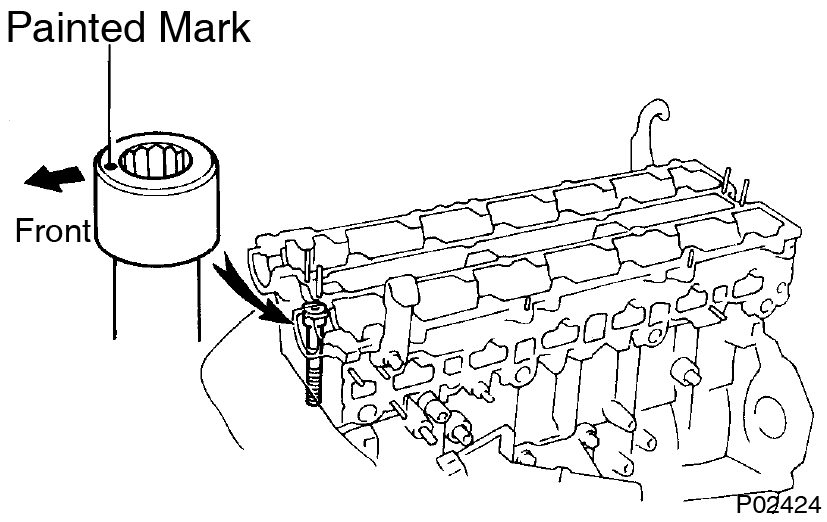

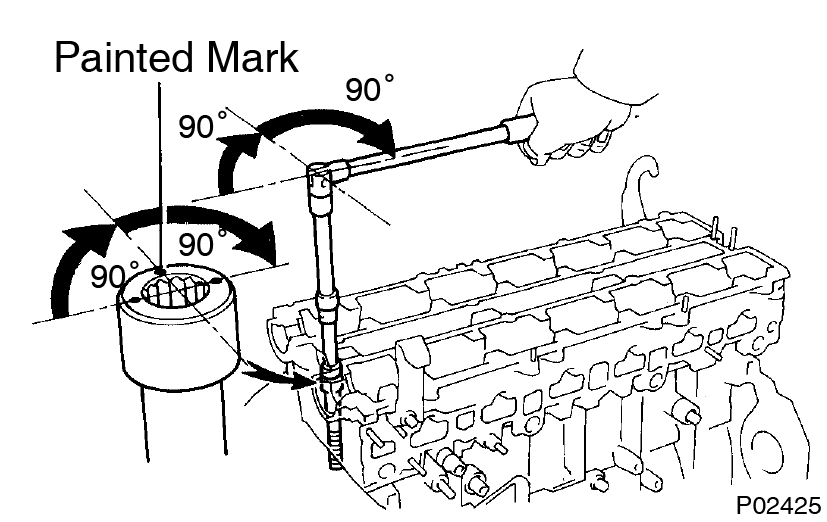

If any of the bolts do not meet the torque specification, replace the bolt. - Mark the front of the cylinder head bolt head with paint.

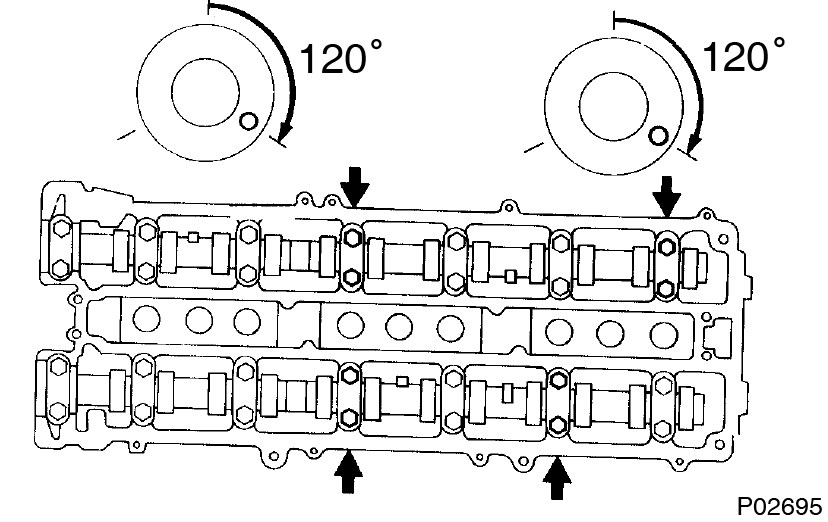

- Retighten the cylinder head bolts 90° in the numerical order shown.

- Retighten cylinder head bolts by an additional 90° shown.

- Check that the painted mark is now turned to the rear.

- Install camshafts

- Apply engine oil to the thrust portion of the camshaft.

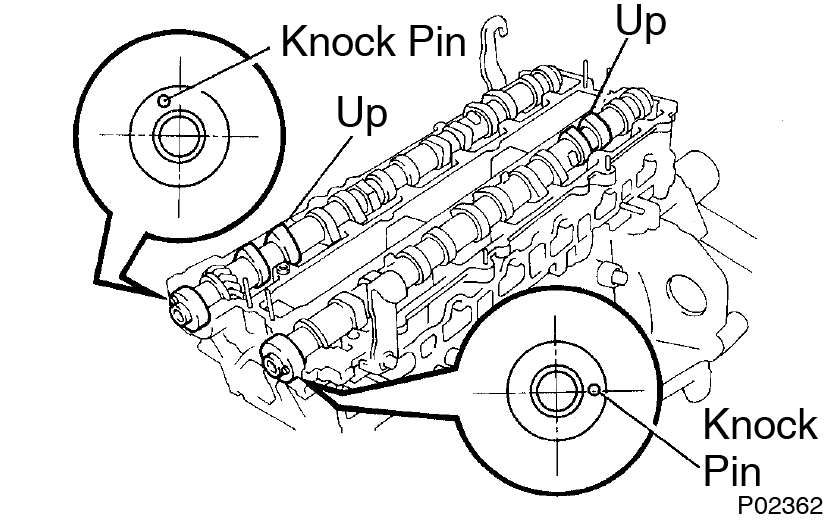

- Place the camshaft on the cylinder head with the cam lobe facing up as shown.

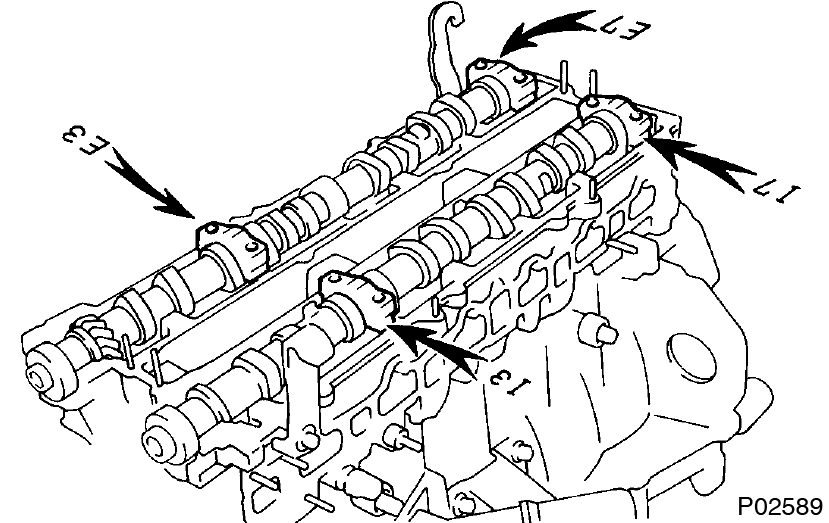

- Place the (Nos. 3, 7 journal) No.2 camshaft bearing caps in their proper location.

- Apply a light coat of engine oil on the threads and under the heads of the bearing cap bolts.

- Temporarily tighten these bearing cap bolts uniformly and alternately, in several passes, until the bearing caps are snug with the cylinder head.

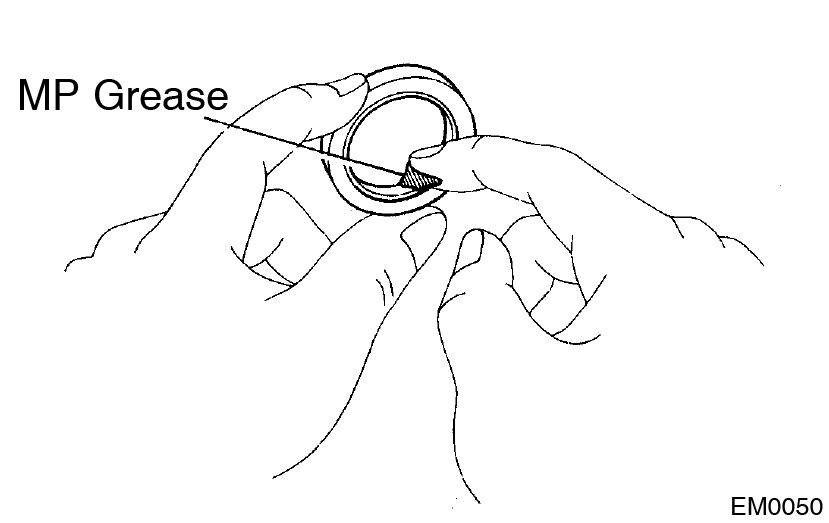

- Apply MP grease to a new camshaft oil seal lip.

- Install the 2 oil seals to the camshafts.

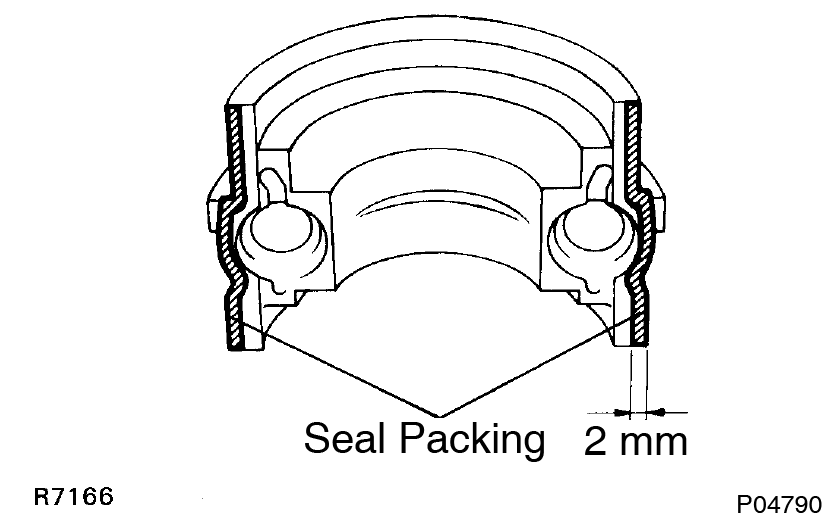

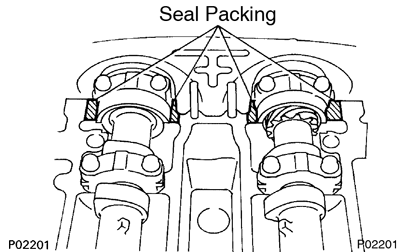

- Clean the installed surfaces of the Nos.1, 3 camshaft bearing caps and cylinder head with cleaner.

- Apply seal packing to the bearing caps as shown.

Seal packing:

Part No. 08826-00080 or equivalent - Install the No.1 , No.2, No.4, No.5 and No.6 bearing caps in their proper locations.

- Apply a light coat of engine oil on the threads and under the heads of the bearing cap bolts.

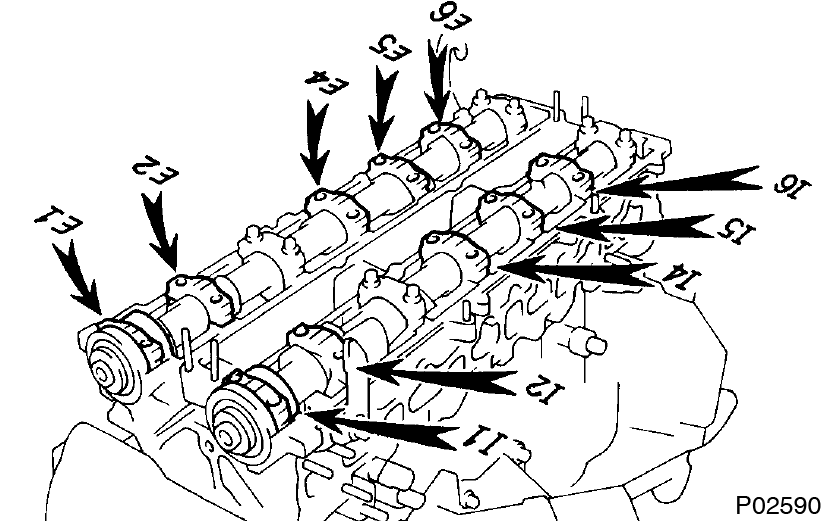

- Install and uniformly tighten the 14 bearing cap bolts on one side, in several passes, in the sequence shown.

Torque: 20 N·m (200 kgf·cm, 15 ft·lbf)

- Using a 5 mm hexagon wrench, the 2 No.3 camshaft bearing cap bolts.

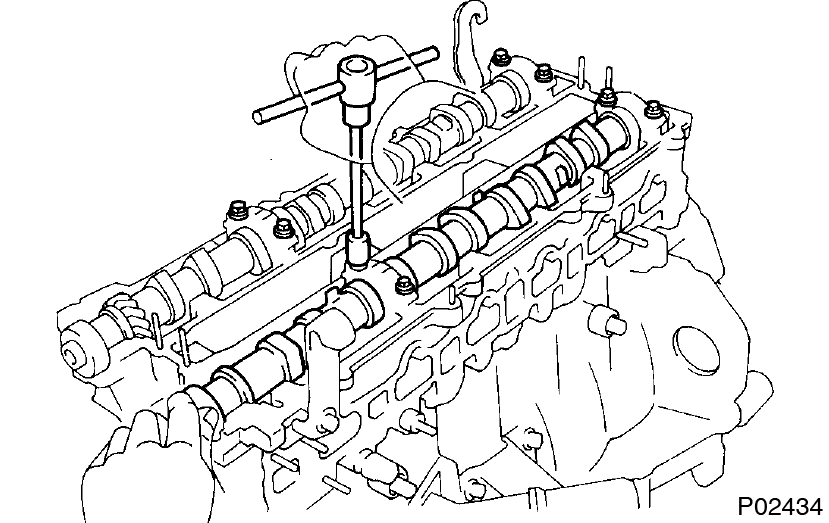

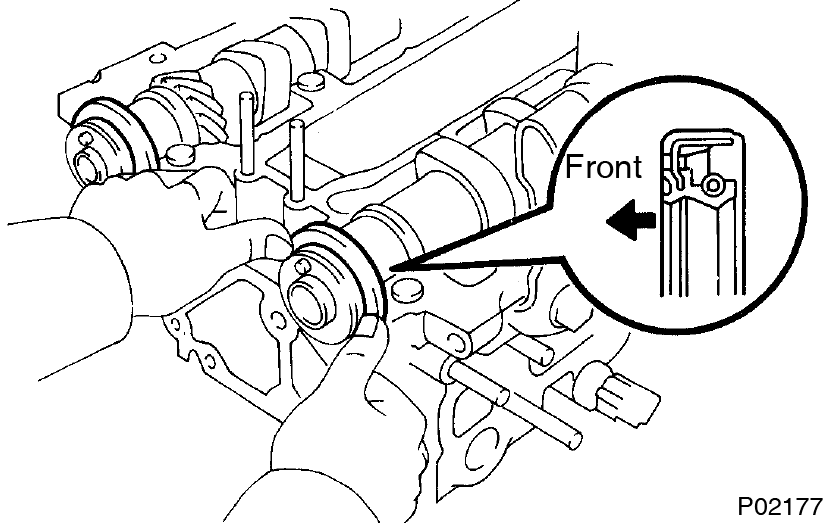

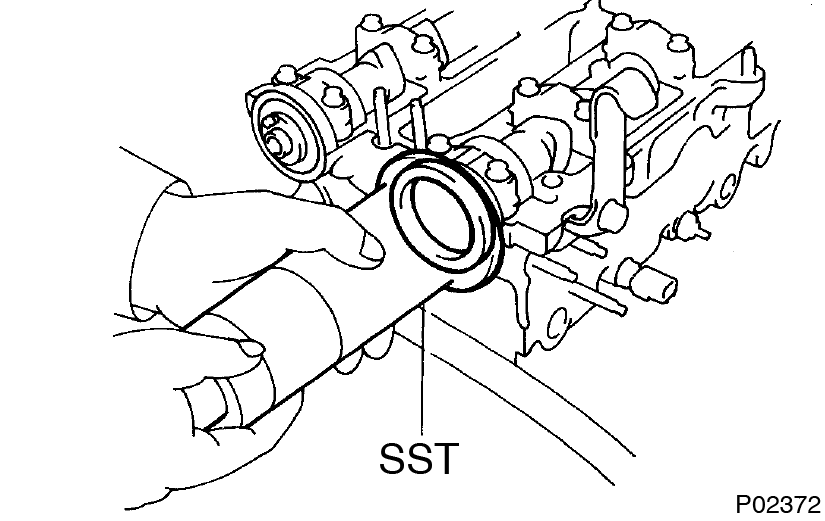

Torque: 5.0 N·m (50 kgf·cm, 44 in.·lbf) - Using SST, push the 2 oil seals in as far as they can go.

SST 09316-6001 1 (09316-00011, 09316-00051)

- Rotate the camshaft with a wrench at the hexagon position, bring the forward straight pin up.

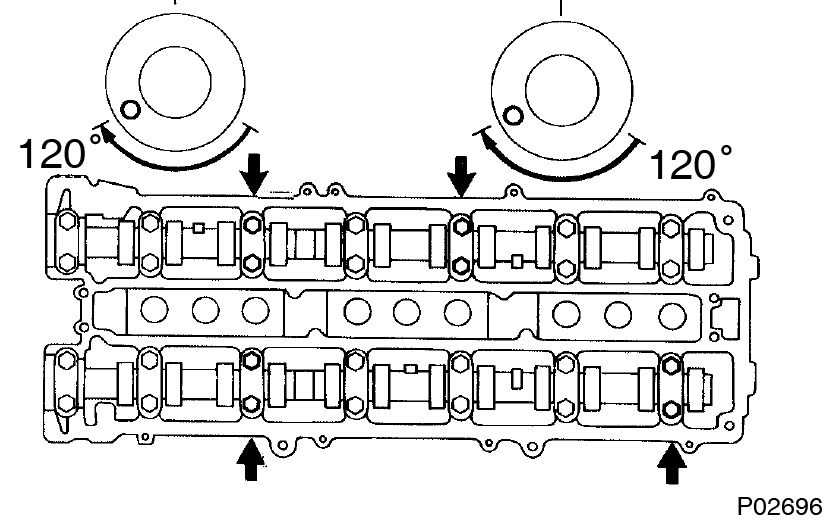

- Loosen the 12 bearing cap bolts as shown, until they can be turned by hand; retighten in several passes. Torque: 20 N·m (200 kgf·cm, 15 ft·lbf)

- Turn the camshaft 1/3 of a revolution.

- Loosen the 8 bearing cap bolts as shown, until they can be turned by hand; retighten in several passes.

Torque: 20 N·m (200 kgf·cm, 15 ft·lbf) - Turn the camshaft a further 1/3 of a revolution.

- Loosen the 8 bearing cap bolts as shown, until they can be turned by hand; retighten in several passes.

Torque: 20 N·m (200 kgf·cm, 15 ft·lbf)

- Apply engine oil to the thrust portion of the camshaft.

- Check and adjust valve clearance (See page EM-4 )

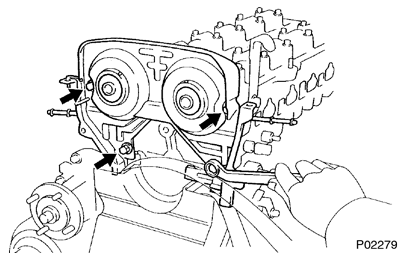

- Install No.4 timing belt cover

Install the timing belt cover with 4 bolts.

Torque: 8.0 N·m (80 kgf·cm, 71 in.·lbf)

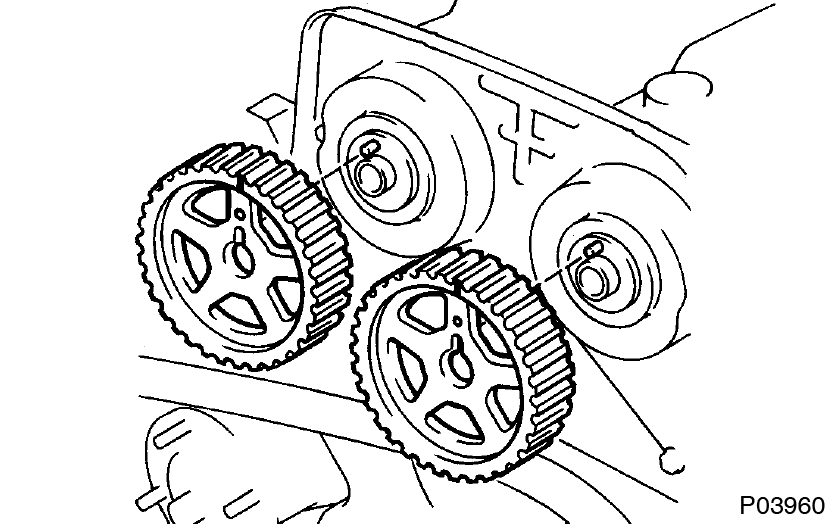

- Install camshaft timing pulleys

- Install the exhaust camshaft timing pulley.

- Align the camshaft knock pin with the groove in the pulley, and slide on the pulley.

- Temporarily install the timing pulley bolt.

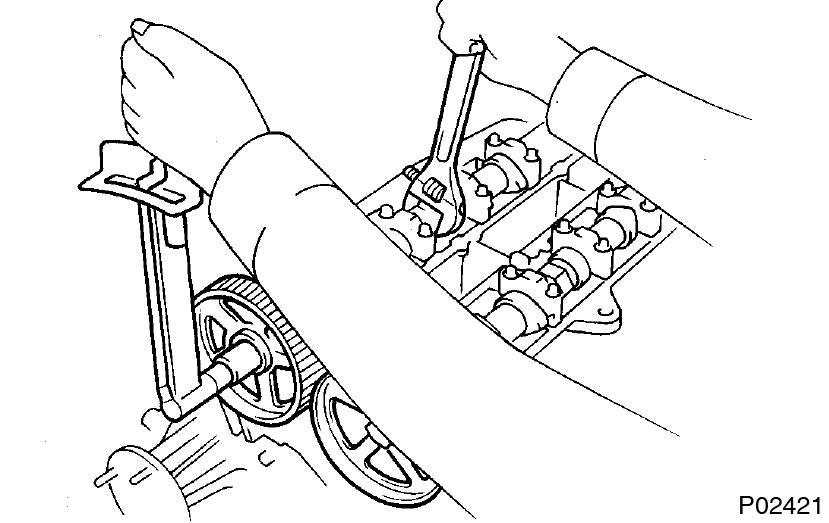

- Hold the hexagon portion of the camshaft with a wrench, and tighten the timing pulley bolt.

Torque: 79 N·m (810 kgf·cm, 59 ft·lbf)

- Align the camshaft knock pin with the groove in the pulley, and slide on the pulley.

- Install the exhaust camshaft timing pulley.

- Install No.3, No.1 and No.2 cylinder head covers

- Remove the any old packing (FIPG) material.

- Apply seal packing to the cylinder head as shown in the illustration.

Seal packing: Part No. 08826-00080 or equivalent - Install the gaskets to the No.1 and No.2 cylinder head covers.

- Install the No.1 cylinder head covers with the 4 bolts.

Torque: 8.3 N·m (85 kgf·cm, 74 in.·lbf) - Install the No.2 cylinder head covers with the 4 bolts.

Torque: 8.3 N·m (85 kgf·cm, 74 in.·lbf) - Install the No.3 cylinder head covers with the 4 bolts and 4 nuts.

Torque: 8.3 N·m (85 kgf·cm, 74 in.·lbf) - Install the PCV valve.

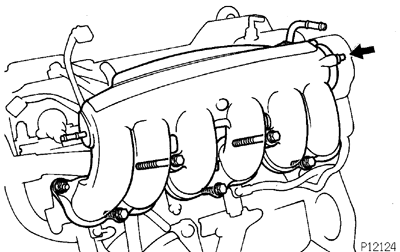

- Install intake manifold assembly

Install the new gasket, the intake manifold and delivery pipe assembly with the 6 bolts and 2 nuts.

Torque: 27 N·m (280 kgf·cm, 20 ft·lbf)

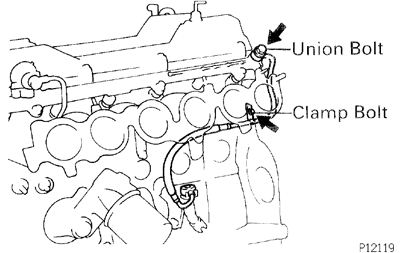

- Install fuel inlet pipe

- Connect the fuel inlet pipe with 2 new gaskets and the union bolt.

Torque: 42 N·m (420 kgf·cm, 30 ft·lbf)

- Install the clam bolt to the intake manifold.

- Connect the fuel inlet pipe with 2 new gaskets and the union bolt.

- Install fuel pressure pulsation damper (See page SF-30)

- Install intake manifold stay

Torque: 39 N·m (400 kgf·cm, 29 ft·lbf) - Install water outlet with water bypass hose

Torque: 21 N·m (210 kgf·cm, 15 ft·lbf) - Connect engine wire

- Install the engine wire protector to the intake manifold with the 3 nuts.

- Connect these connectors:

- 6 injector connectors The No.1, No.3 and No.5 injector connectors are dark gray, and the No.2, No.4 and No.6 injector connectors are gray.

- ECT sensor connector

- ECT sender gauge connector

- A/C compressor connector

- . Oil level sensor connector

- Oil pressure switch connector

- 2 knock sensor connectors

- 6 injector connectors

- Install the wire clamp to the fuel return pipe.

- Install the 2 ground straps to the intake manifold with the bolts.

- Connect these connectors:

- Crankshaft position sensor connector

- Heated oxygen sensor (bank 1 sensor 1) connector

- Connect the wire clamp to the bracket.

- Install timing belt (See page EM-19)

- Install spark plugs

- Install distributor and high-tension cords assembly (See page IG-18)

- Connect high-tension cords to cylinder head covers (See page IG-10)

- Install No.3 timing belt cover

- Install cylinder head rear cover

- Install air intake chamber

- Install a new gasket and the intake chamber with the 5 bolts and nut.

Torque: 27 N·m (280 kgf·cm, 20 ft·lbf) - Install the bolt holding the engine wire protector to the air intake chamber.

- Connect these hoses:

- Vacuum hose to brake booster union

- EVAP hose to No.2 vacuum pipe

- Install a new gasket and the intake chamber with the 5 bolts and nut.

- Install DLC1 bracket and VSV assembly

- Install vacuum control valve set

Torque: 21 N·m (210 kgf·cm, 15 ft·lbf) - Install No.2 vacuum pipe and VSV assembly

Torque: 27 N·m (280 kgf·cm, 20 ft·lbf) - Connect EGR GAS temperature sensor connector

- Install oil dipstick and guide for engine (See page LU-16 )

- Install oil dipstick and gauge for transmission (See page EM-64)

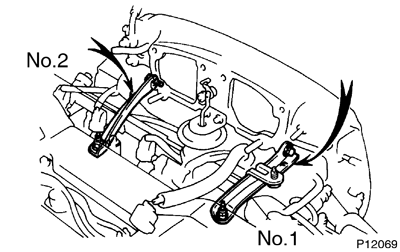

- Install air intake chamber stays

The No.1 stay is marked with ”F”, and No.2 stay is marked with ”R”.

The No.1 stay is marked with ”F”, and No.2 stay is marked with ”R”.- Install the No.1 stay with the bolt and nut.

Torque: 18 N·m (185 kgf·cm, 13 ft·lbf) - Install the No.2 stay with the bolt and nut.

Torque: 18 N·m (185 kgf·cm, 13 ft·lbf)

- Install the No.1 stay with the bolt and nut.

- Install throttle body and intake air connector assembly (See page SF-25)

- Install engine wire bracket

- Connect fuel return hose

- Install PS pump

- Install the pump rear stay with the 2 bolts.

Torque: 39 N·m (400 kgf·cm, 29 ft·lbf) - Install the vane pump with the 2 bolts.

Torque: 58 N·m (590 kgf·cm, 43 ft·lbf) - Connect these hoses:

- PS air hose to No.4 timing belt cover

- PS air hose to air intake chamber

- Install the pump rear stay with the 2 bolts.

- Install No.1 water bypass pipe and water bypass outlet (See page CO-1 1)

- Install exhaust manifolds

- Install a new gasket and the exhaust manifold with 4 the nuts. Install the No.1 and No.2 exhaust manifolds.

Torque: 39 N·m (400 kgf·cm, 29 ft·lbf) - Connect the 2 heated oxygen sensor connectors.

- Install a new gasket and the exhaust manifold with 4 the nuts. Install the No.1 and No.2 exhaust manifolds.

- Install No.2 front exhaust pipe (See page EM-64)

- Install drive belt

Install the drive belt by turning the drive belt tensioner clockwise. - Install air cleaner, MAF meter and intake air connector pipe assembly

- Install air cleaner dust

- Fill with engine coolant

- Start engine and check for leaks

- Check ignition timing (See page IG-18 )

- Install engine under cover

- Road test

Check for abnormal noise, shock, slippage, correct shift points and smooth operation. - Check engine coolant level